- +33 (0)4 68 37 40 00

- 1 Rue des Fenouillèdes, 66280 Saleilles

- Monday - Thursday : 8:00 a.m. - 5:00 p.m. / Friday: 8:00 a.m. - 4:00 p.m.

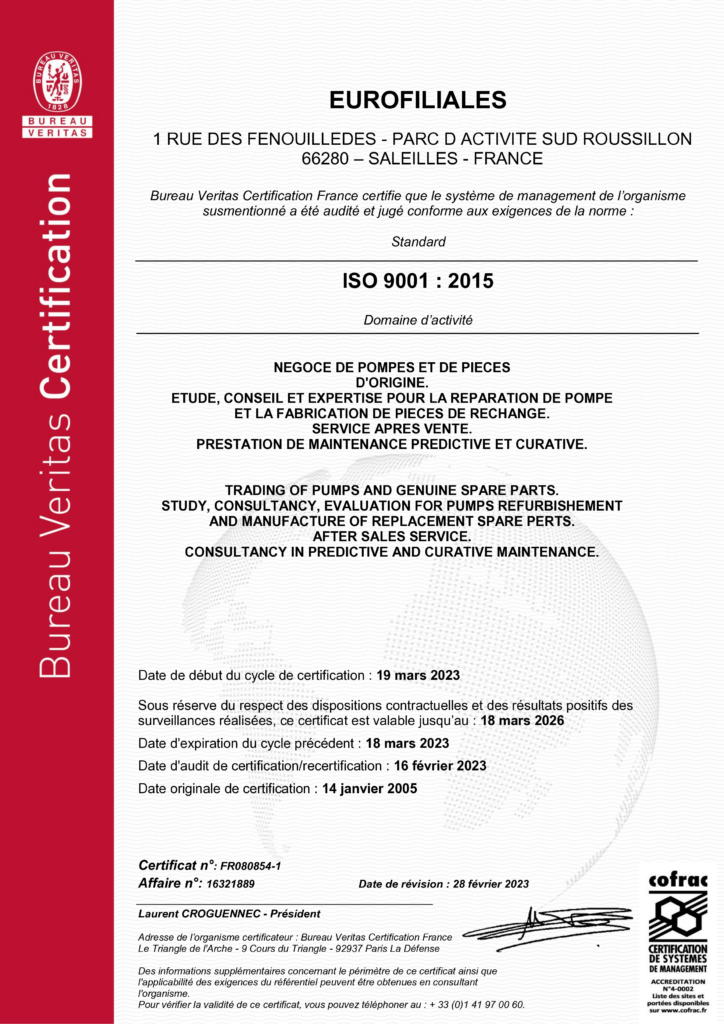

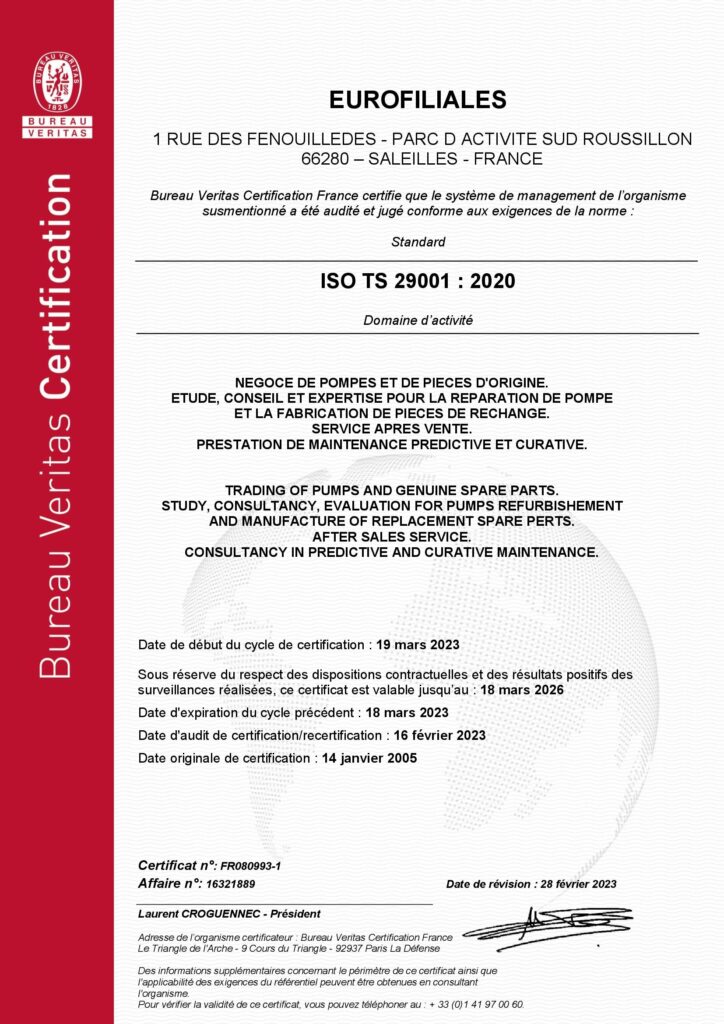

Our quality approach puts customer satisfaction at the heart of our ISO 9001 and TS29001 procedures. The implementation of this quality management system commits us and guarantees you the consideration of your requirements, monitoring and traceability at the highest level. Our sustainable development approach integrates all social, economic and environmental concerns related to our business and customer relationships. The HSE principles are rooted in the culture of Eurofiliales and its partners since the beginning of their activities. Our HSE approach is developed on all our sites and involves all of our employees. Our quality department ensures its efficiency and its impact on customer satisfaction

In order to maintain the confidence of our customers and to sustain our relations, the implementation of an integrated management approach has become a goal for the company since 2003. The requirements of the ISO 9001 Quality Reference: 2015 are suitable for our company's culture:

Developed by the ISO/TC67 Technical Committee, responsible for the standardization of offshore equipment, equipment and structures used in the petroleum industries, ISO/TS 29001 defines a specific quality management dedicated to the oil sector. Twin sister of API Spec. Q1, it incorporates additional requirements for production processes to ensure maximum customer satisfaction.

The API 610, an American version of ISO 13709, is an international benchmark for centrifugal pumps used in the oil, petrochemical and gas industries. The high level of requirements therefore makes it a guarantee of safety for the end user. For each work, EUROPEAN ensure compliance with, and in accordance with, the refurbishing process.

API 610, ISO TS29001 Customer references oil industry

ISO9001: articles

International centrifugal pump repair company, specialized in reverse engineering, on-site interventions, since 1994 we have been striving to guarantee quality and experience for our customers.