- +33 (0)4 68 37 40 00

- 1 Rue des Fenouillèdes, 66280 Saleilles

- Monday - Thursday : 8:00 a.m. - 5:00 p.m. / Friday: 8:00 a.m. - 4:00 p.m.

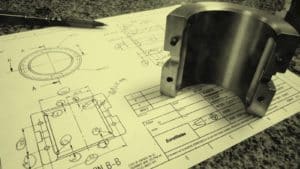

The objective of a survey is to draw up a precise state of the art of a plant and to extract a maintenance philosophy.

A survey contains:

Equipped with the most advanced measuring devices, our technicians combine each operating parameter in a complete report, allowing to establish a maintenance plan and thus a personalized maintenance philosophy for the customer.

This survey also enables an on-site maintenance audit to be carried out and to propose, if necessary, Training adapted to improve and optimize maintenance.

It also enables the state of stocks to be established and plans to be made for the future. optimization by preparing repair kits of type R1, R2, R3, R4.

Following survey Our comprehensive team helps you manage your spare parts inventory by conducting an audit of your store. This is done by drawing up lists of necessary parts according to the levels of intervention known for centrifugal pumps, mechanical linings and speed reducing/multiplier. Taking into account all the technical aspects of the equipment, we recommend the quantity to be stored taking into account the criticality of the machine in case of shutdown, the average time of supply and the cost.

Being able to be practiced at our premises or at our partners, EUROFILIALES offers various training sessions, such as:

International centrifugal pump repair company, specialized in reverse engineering, on-site interventions, since 1994 we have been striving to guarantee quality and experience for our customers.