The objective of a survey allows to perform a precise inventory of an entire installation and extract a maintenance philosophy.

A survey contains:

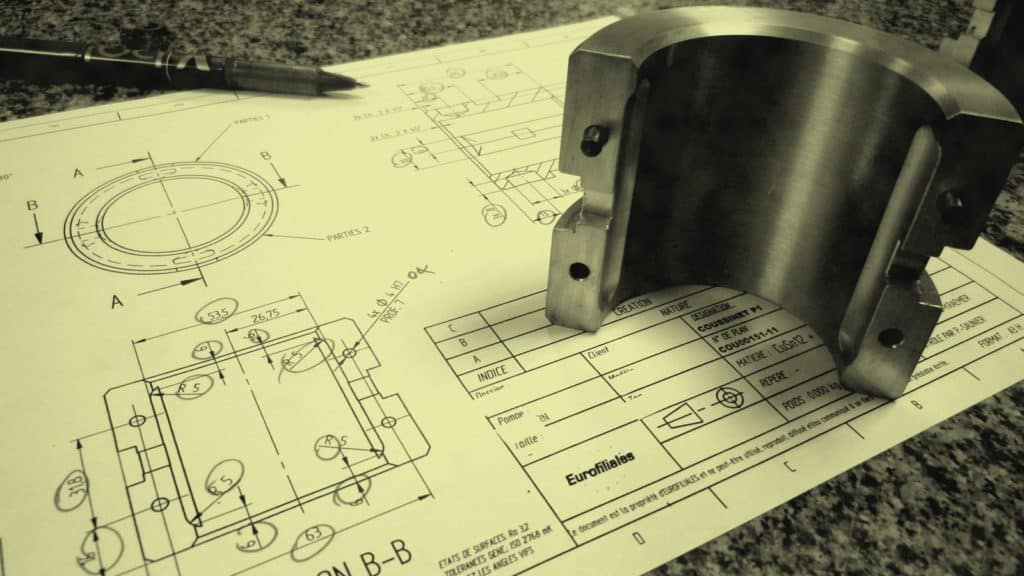

Equipped with the most advanced measuring devices, our technicians gather each operating parameter in a complete report, allowing to establish a maintenance plan and thus a personalized maintenance philosophy for the customer.

This survey also allows to make an audit of the maintenance on site and to propose, if necessary, adapted trainings in order to improve and optimize the maintenance.

A status of stocks can be done in order to plan its optimization by preparing repair kits of type R1, R2, R3, R4.

Following a complete survey, our team helps you in your spare parts inventory management by performing an audit of your warehouse. This is done by establishing lists of necessary parts according to the known levels of interventions for centrifugal pumps, mechanical seals and gearboxes. Taking into consideration all the technical aspects of the material, we advise the quantity to be stocked considering the criticality of the machine in case of shutdown, the average supply time and cost.

EUROFILIALES offers a variety of training sessions (in our workshop or at our partners) such as: